Our specialty is working with you to develop the best method for joining difficult to weld materials and/or complex geometry.

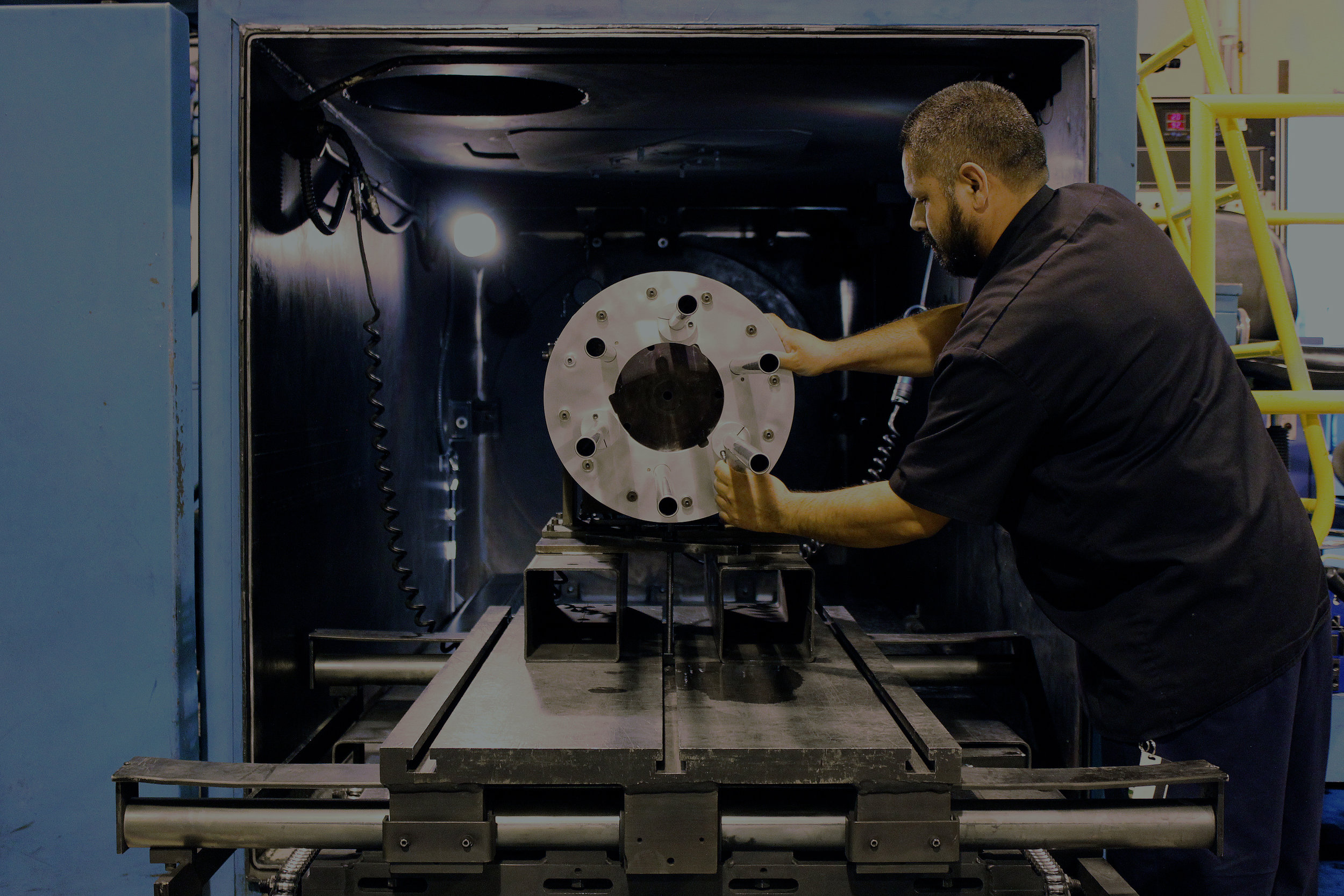

ATCo utilizes high voltage style electron beam welders which permit a narrower beam profile and lower distortion than low voltage style machines. ATCo is vertically integrated; self-sufficient in developing tooling, maintaining equipment, determining processing and handling final inspection.

Why choose Advanced Technology?

ATCo's wide range of equipment, with multi-part positioners, allows high volume, cost-effective welding.

- Various chamber extensions permit welding of very long parts, over 200 inches.

- Large diameter parts, can be handled in two different welders.

- One of the most experienced EB welding facilities in the U.S.

- Over 40 years of experience.

ATCo has a complete range of support services to complement its EB activity - a partial list is:

- Pre-weld and post-weld machining

- Helium leak testing

- Metallographic inspection

- Heat Treating / Stress Relieving

- Tooling design and manufacture

- Design assistance

What is Electron Beam Welding?

Electron Beam Welding provides consistent weld size and high joint strength. Welding of thick to thin material and dissimilar metals is easily accomplished. EB welding permits joining of reactive and refractive materials. Materials considered difficult to weld by conventional processes may often be welded using the EB welding process. EB welding is able to achieve deep penetration narrow welds providing low distortion. The narrow heat affected zone (HAZ) allows joining parts in the finished or near finished shape. Heat sensitive parts benefit from the low overall heat input.

Typical Applications

The following is a list of typical metals that ATCO has processed:

- Aluminum Alloys

- Stainless Steel & Precipitation Hardening Alloys

- Low & High Alloy Steels

- Nickel & Cobalt Alloys

- Titanium Alloys

- Copper Alloys

- Refractory Metals