ATCo provides both conventional and automated GTAW. The manual GTAW stations are supported with modern welding machines, rotary positioners and "Glove Boxes."

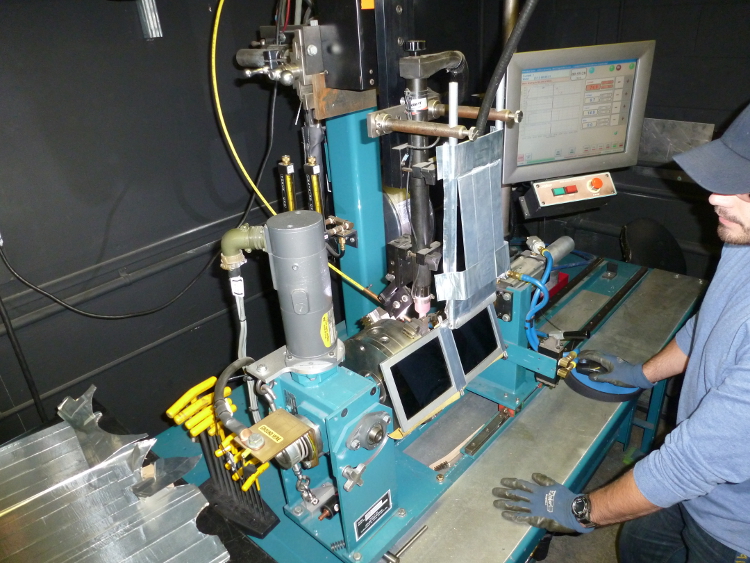

The automated work station features an AcuWeld system that provides a computer controlled precision gas tungsten arc welding process, as well as a plasma arc process. The AcuWeld system provides machine tool type positioning of the weld arc/filler wire, along with accurate part manipulation. Key to the effectiveness of this automated welder is its capability to coordinate the wire feed delivery rate to the programmed current pulse characteristic. The system also monitors all process parameters essential in producing quality weldments.

Why choose Advanced Technology?

Trained and certified welders.

Properly maintained modern welding power supplies.

Fully automated AcuWeld system for multi-part production.

System holds close positioning accuracy and assures proper weld parameters.

What is Gas Tungsten Arc Welding?

Gas Tungsten Arc Welding provides high-quality welds because of the gas shielding of the molten weld pool. The welding arc is created between a tungsten electrode, which is non-consumable, and the weld pool. The welding can be autogenous (without filler material), or with filler rod/wire. Because of the shielding and high concentration of heat it is used on refractory and reactive metals which oxidize readily without inert gas protection.

Typical Applications

Some examples of ATCo's GTA welding: 300 Series, 400 Series and precipitation hardening stainless steels, Inconel 718, Incoloy 901, A286 and Titanium alloys.